Lab 13.56Mhz 2L Plasma Cleaner System 100W/150W With Stainless Steel Chamber

Plasma cleaning machine divided into two types, atmospheric and vacuum; it is widely used in semi-conductor, PCB, medical diagnosis, elastomer industry, optical industry,etc.

| Model No. | OLT-PS-2L |

| Product Name | 2L Plasma Cleaner |

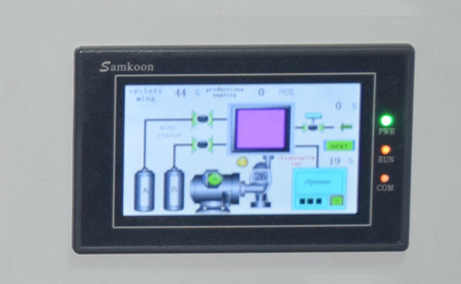

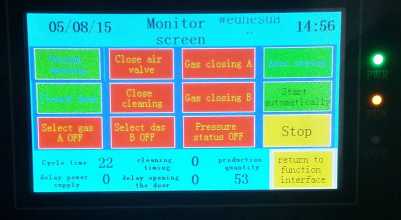

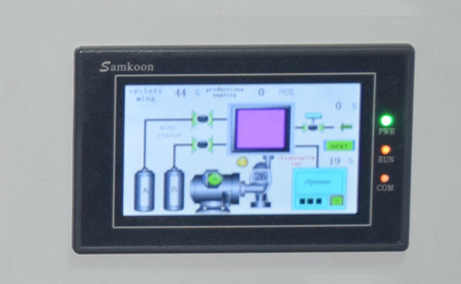

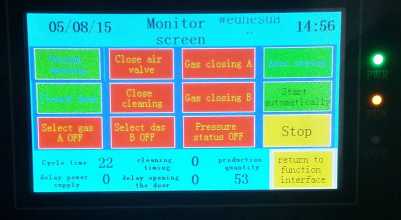

| Display | LCD touch controller

|

| Working voltage | AC 108V-240V, 50Hz |

| RF Frequency | 40KHz (13.56MHz for optional) |

| Coupled mode | condenser coupling, without pollute sample |

| RF power | 200 w |

| RF offset | < 0.2KHz |

| Characteristic impedance | 50Ω, automatic matching |

| Vacuum degree | 10-100Pa, equipped with a mechanical pump

If request high vacuum, please select our turbo pump system

(Optional) |

| Gas speed | Two way Float Flow Gas Control10-100ml/min, adjustable

|

| Control | PLC Touch Panel Program controlAuto/Manual two mode for optional

|

| Inner chamber size | Stainless Steel Chamber with Φ 100*270mm

If Chamber is not enough for using, we have Φ 150*270mm (capacity: 5L)200* 200*260mm (capacity: 10L)for optional |

| Pressure Gauge | A simple digital pressure gauge is equipped for reading

If request high precision vacuum reading, please select digital vacuum gauge:

(Optional) |

| Cooling way | Forced cooling |

| Outer dimension | 440*390*200mm |

| Gross weight | 35 kg |

| Time of delivery | 10 working days after receive the payment |

1. Environmental technologies: plasma process is the role of gas - solid coherent reactor consumes no water resources, no need to add chemicals and no environmental pollution.

2. Wide adaptability: regardless of processing substrate type, such as metals, semiconductors, oxides, and most of the polymer material can be a good deal;

3. Low temperature: close to room temperature, particularly suitable polymer materials, have a longer retention time and a higher surface tension than the corona and flame method.

4. Multifunctions: it involves only a shallow surface of polymer materials (10 -1000A), while preserving the characteristics of the material itself can give it one or more new features;

5. Low cost: the device is simple, easy operation and maintenance, continuous operation,a few bottles of gas can replace thousands of kilograms cleaning fluid

6. The whole process technology can be controlled: all the parameters can be setted by the computer and data recording

7. Treated geometry Unlimited: Big or small, simple or complex, parts or textiles can be processed.