Vacuum Plasma Cleaner For PC Material And Silicone Rubber

Vacuum Plasma Cleaner For PC Material And Silicone Rubber

Model Number:

OLT-PS-15

Compliance:

CE Certified

Minimum Order Quantity:

1

Voltage:

108V-380V 50/60HZ

Warranty:

3 year

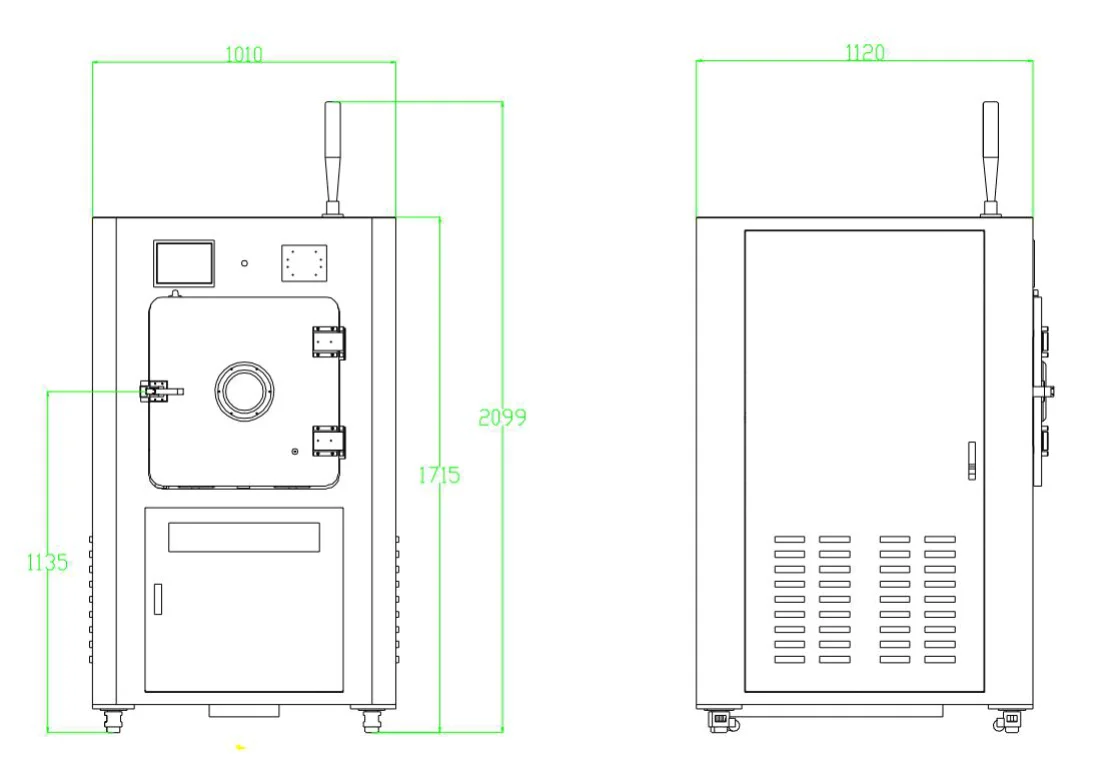

Dimension(L*W*H):

885*900*1576mm

Weight:

350kg

Packaging Details:

Export wooden package

Delivery Time:

8-10 day

Vacuum plasma cleaner For PC Material And Silicone Rubber

| Power Systems | Custom RF power supply:13.56MHz 0-600W(Adjustable) |

| Fully automatic vacuum capacitor matcher | |

| Vacuum system | Custom two-stage rotary vane pump(Oil pump):40m3/h |

| Vacuum gauge: Japan Inficon Pirani vacuum gauge | |

| Vacuum line: all stainless steel line high strength vacuum bellows | |

| Cavity system (customizable) | Aluminum alloy material;Military grade welding 25mm thickness |

| Cavity internal dimensions:375*375*425mm(W*H*D) | |

| Electrode plate layout:Horizontal arrangement, extractable | |

| Work tray | |

| Space layer number:6 layers | |

| Gas system | Pneumatic valve:Japan SMC |

| Flow meter:China SevenStar:0-300SCCM | |

| Two process gases:Argon, oxygen (Argon, oxygen, nitrogen, hydrogen, four nitrogen fluoride are optional.) | |

| Control system | PLC:German SIEMENS S series |

| Seven inch touchscreen: WEINVIEW | |

| Electrical parts:Schneider | |

| Other parameters | Dimensions:885*900*1576mm(W*H*D) |

| Weight:350kg | |

Color:Silver |

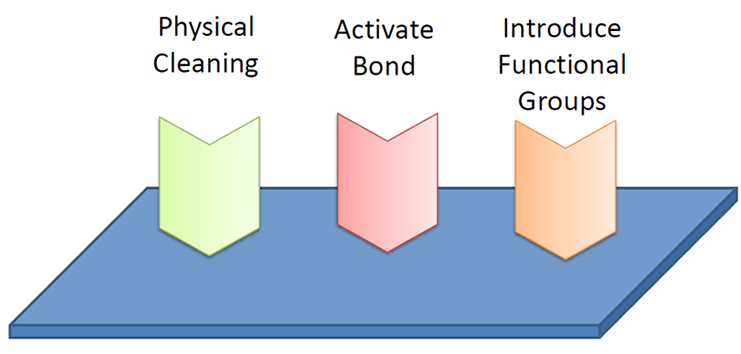

Plasma cleaning is an important material surface modification method and has been widely used in many fields.

And some traditional cleaning methods, such as ultrasonic cleaning, UV cleaning, etc., have the following advantages:

(A)Low processing temperature

The processing temperature can be as low as 80 ° C - 50 ° C. Low processing temperatures ensure no thermal effects on the sample surface.

(B)No pollution during the whole process

The plasma cleaner itself is a very environmentally friendly device that does not cause any pollution,and does not cause any pollution during the treatment process.

(C)Stable processing effect

The treatment effect of plasma cleaning is very uniform and stable, and the effect of maintaining the sample after a long period of time is good.

(D)Can handle samples of various shapes

For complex shaped samples, plasma cleaning can find the right solution.

Vacuum plasma cleaning allows for the cleaning of the internal position of the solid sample.

Product principle

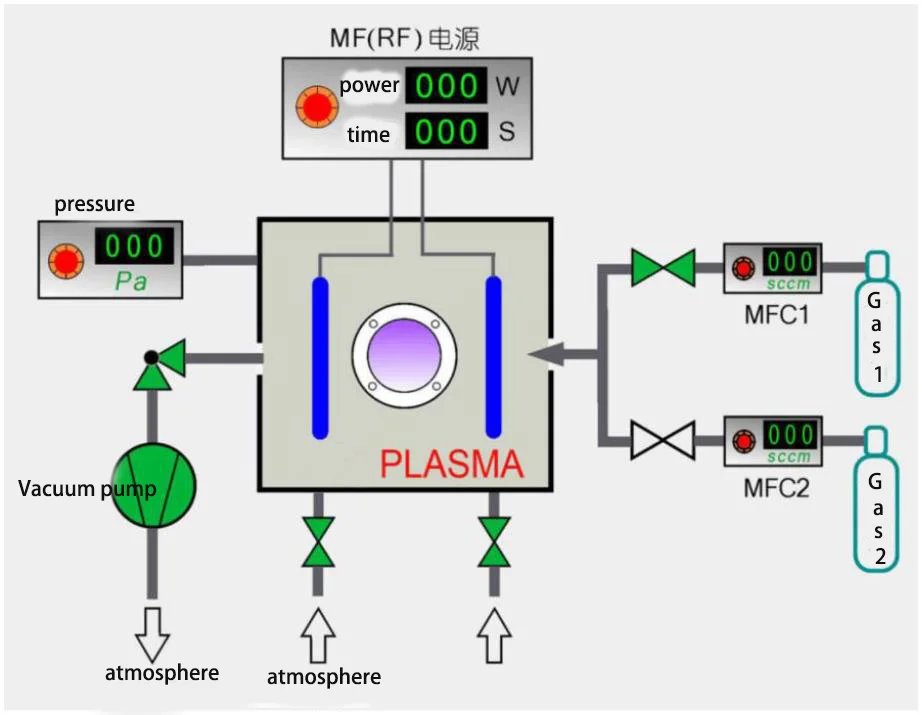

The structure of the plasma cleaner is mainly divided into five major components: control system, Excitation power system, vacuum chamber, process gas system, and vacuum pump system.

(A)Cobtrol System

The function of the control system is to control the operation of the entire device, including human-machine interface (touch screen), PLC, electrical circuit. Vacuum plasma cleaning with fully automatic control system enables multiple modes and multiple programs to control the cleaning equipment to meet the needs of different customers.

(B)Excitation power system:

There are three main types of excitation power: 40KHz intermediate frequency excitation power supply, 13.56MHz RF excitation power supply, and 2.45GHz microwave excitation power supply. At present, the industry mainly uses RF excitation power supply and intermediate frequency excitation power supply.For different applications.

(C)Vacuum chamber:

The vacuum chamber is mainly divided into three materials: 1) aluminum alloy cavity, 2) stainless steel vacuum chamber, 3) quartz cavity. Different discharge modes and different sample sizes and capacities can be achieved depending on the user's different needs.

(D)Process gas system:

Process gases include flow meters, pneumatic valves, etc. Users can flexibly choose multiple process gas solutions, argon, oxygen, hydrogen, nitrogen, carbon tetrafluoride, etc., to meet different process requirements. Clean the surface of various products.

(E)Vacuum pump:

The vacuum pump is divided into an oil pump, a dry pump and a Roots pump. The oil pump mainly adopts a two-stage rotary vane pump, and the vacuum pump is formulated according to the volume, work efficiency and environmental requirements of the user.

Scan To Wechat