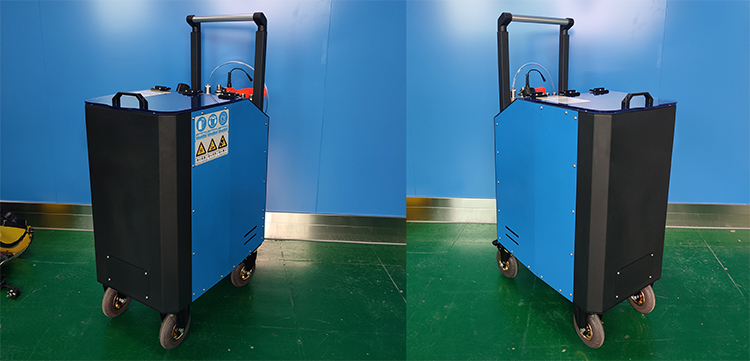

Printing Industry Removing Ink Dry Ice Cleaning Machine

Dry ice jet medium dry ice particles accelerate in high-pressure air flow and impact the surface to be cleaned.

Lead Time:

3-5 days

Model Number:

B3+

Compliance:

CE Certified

Minimum Order Quantity:

1

Voltage:

AC220V

Power:

370W

Warranty:

1 year

Dry ice blasting is a revolutionary blasting method that uses small, compact dry ice pellets as the blasting material. The dry ice pellets are accelerated in a jet of compressed air similar to that used in traditional blasting methods. dry ice blasting will often allow a company's production equipment to be cleaned while in operation without the need for dismantling and costly downtime. Dry Ice Blasting is non-abrasive, and surfaces are therefore treated gently. The system can thus be used on easily-damaged surfaces like nickel, chromium and soft aluminum. The process is dry, and no waste materials are produced. This means that cleaning can be carried out even during short production shutdowns.

Parameter

Model | A625 | A730 | B3 | B3+ | T6 |

Voltage | AC220V | AC220V | AC220V | AC220V | AC220V |

Airflow | 1-12.0m3/min | 2-12.0m3/min | 1-4.0m3/min | 0.5-4.0m3/min | 0.5-4.0m3/min |

Pressure | 0.2-1.6Mpa | 0.2-1.6Mpa | 0.1-0.8Mpa | 0.1-0.85Mpa | 0.1-0.8Mpa |

Dry ice blasting volume | 0-2kg/min | 0-4kg/min | 0-1.2kg/min | 0-1.2kg/min | 0-0.6kg/min |

Capacity | 15kg | 25kg | 10kg | 13kg | 10kg |

Power | 0.75Kw | 0.75Kw | 0.37Kw | 0.37Kw | 0.37Kw |

Equipment weight | 56.5kg | 75kg | 40kg | 55kg | 50kg |

Overall dimensions | 44* 68* 78cm | 40*77*92cm | 51*30*71cm | 60*40*85cm | 51*30*71cm |

Unlike other jet media, the temperature of dry ice particles is very low (- 78 ℃). Such low temperature makes Dry Ice Cleaning have unique thermodynamic properties and affect the mechanical properties of adhering dirt. Thermal shock occurs due to the temperature difference between the dry ice particles and the cleaning surface. When the temperature of the material decreases and the brittleness increases, the dry ice particles can impact and break the dirt layer.

Accessories

Feature

Using the most advanced dry ice air pressure mixing feeding system, the industry's unique quick-change rollers are matched with different caliber nozzles, which can be applied to: EVA molds in the printing industry, petrochemical industry, foundry industry, vulcanization molds, motor power, aviation and aerospace industries, Heating industry, metal surface rust and paint removal, fan impeller surface coating, second-hand refurbishment and other industrial cleaning.

Working Principle

Dry ice blast cleaning (dry ice blast cleaning), also known as cold spray technology, uses compressed air as a power and carrier, and uses dry ice particles as accelerated particles. The dry ice particles are sprayed out at a rate close to the speed of sound through a dedicated dry ice blast cleaning machine. , And carry a large amount of kinetic energy. When it collides with the surface of the dirt, the above-mentioned kinetic energy is transferred to the dirt. The dry ice instantly expands about 800 times the volume of the body, forming a physical cleaning method that embrittles the dirt and peels off the surface of the object. Because dry ice blasting volatilizes and sublimates instantaneously, it will not cause any damage to the surface of the object.

Feature

Using the most advanced dry ice air pressure mixing feeding system, the industry's unique quick-change rollers are matched with different caliber nozzles, which can be applied to: EVA molds in the printing industry, petrochemical industry, foundry industry, vulcanization molds, motor power, aviation and aerospace industries, Heating industry, metal surface rust and paint removal, fan impeller surface coating, second-hand refurbishment and other industrial cleaning.

Working Principle

Dry ice blast cleaning (dry ice blast cleaning), also known as cold spray technology, uses compressed air as a power and carrier, and uses dry ice particles as accelerated particles. The dry ice particles are sprayed out at a rate close to the speed of sound through a dedicated dry ice blast cleaning machine. , And carry a large amount of kinetic energy. When it collides with the surface of the dirt, the above-mentioned kinetic energy is transferred to the dirt. The dry ice instantly expands about 800 times the volume of the body, forming a physical cleaning method that embrittles the dirt and peels off the surface of the object. Because dry ice blasting volatilizes and sublimates instantaneously, it will not cause any damage to the surface of the object.

Xiamen OLLITAL Technology Co., Ltd. It is specialized in the research, production, sales and service related supporting equipment of one-stop service, dry ice jet cleaner, Dry Ice Granulator, plasma cleaner, laser cleaner, Ultrasonic cleaning and high-temperature steam cleaner in the cleaning industry. We can develop machines according to customer needs and provide one-stop services for dry ice cleaning technology. Dry ice cleaning machines are an efficient, environmentally friendly, and safe cleaning method widely used in multiple industries, including molds, machinery, circuit boards, etc. Only by properly controlling nozzle design, pressure control, cleaning agent control, and operating techniques can dry ice cleaning machines achieve maximum cleaning efficiency. Our efficient, environmentally friendly, safe, and flexible cleaning equipment has earned us a good reputation in the industry and has been sold to over 30 countries worldwide. With the continuous increase in labor management costs and land costs, automated equipment will definitely replace semi-automatic or manual production in the future. This is a trend in social development. Facing opportunities and challenges, Lingtie will stick to its original intention and continue to move forward.

Xiamen OLLITAL Technology Co., Ltd. was established in 2003, with more than 150 employees (as of August 2022). OLLITAL Technology is a company focusing on R&D and specializing in the production of industrial cleaning machinery, dry ice pellet machinery, dry ice cleaning machinery, and Plasma cleaning machines. , Laser cleaning machinery, ultrasonic equipment and other fields of products.

OLLITAL is a professional company with more than 10 years of experience in the cleaning industry. We are committed to providing comprehensive cleaning solutions, covering a series of cleaning equipment such asdry ice cleaning machines, Dry Ice Making Machines, Plasma cleaning machines, Ultrasonic Cleaning Machines, Laser cleaning machines, etc. OLLITAL is a one-stop solution provider for the cleaning industry. We use our excellent technology and professional team to provide customers with efficient and reliable cleaning equipment and services.

OLLITAL has gathered a professional team composed of experts, scholars and other scientific researchers. The company's independently developed dry ice cleaning machines, dry ice making machines, Ultrasonic cleaning machines, plasma cleaning machines, laser cleaning machines and other products have obtained patents and expanded marketing.

OLLITALhas a high reputation in more than 70 countries and regions, providing technical support to tens of thousands of organizations to solve problems in their research, especially universities, research institutes, industries, inspection agencies, etc. We have long-term business partners in more than 130 countries.

OLLITAL always adheres to the mission of "service first, achieving the future" and vigorously promotes corporate culture. OLLITAL is willing to establish win-win business cooperation with dealers around the world with high-quality products and good services.

OLLITALis a testament to excellence in technological innovation and manufacturing. With its commitment to quality and environmental responsibility, OLLITAL was awarded several prestigious Certifications between 2010 and 2022, including ISO 9001, ISO 14001, CE, NSF, EN and FDA. Demonstrates the company's ongoing commitment to meeting and exceeding international standards.

Q1. What is your products range?

• Ollital Technology It is a high-tech enterprise focused on research and development, specializing in the production of industrial cleaning machinery, dry ice particle machinery, dry ice cleaning machinery,plasma cleaning machine, laser cleaning machinery, ultrasonic equipment and other fields of products.

Q2. Are you trading company or manufacturer?

• We are a professional manufacturer of Dry ice cleaning industry, and we have our own factory.

Q3. Do you provide samples? Is it free?

• Yes, we could offer the sample. Considering the high value of our products, the sample is not free, but we will give you our best price including shipping cost.

Q4. Do you have warranty?

• Yes, we offer 1 year warranty for the spare part.

Q5. How long is your delivery time?

• Generally it is within 7 working days after receiving the payment if the goods are in stock. Or it is 15 working days if the goods are not in stock, depending on order quantity.

Q6. What is your terms of payment?

• Payment≤15,000USD, 100% in advance. Payment≥15,000USD, 70% T/T in advance, balance before shipment.

(If you are concerned about payment security for the first order, we advise you can place Trade Assurance Order via Alibaba.We have a flagship store on Alibaba International Station you will get 100% payment refund if we can't meet agreed delivery time.)

OLLITAL(Click the link below to contact directly)

Add.: Haicang District, Xiamen , Fujian , China.

WhatsApp: +8615960821529 Tel.: +86 15960821529

Email: kevin@ollital.com Skype: +8615960821529

Scan To Wechat